Without a product prototype, your product idea probably isn't going to go anywhere. Not only do prototype products have a lot more success when it comes to being funded on crowdfunding platforms, but prototypes are a great way to start marketing your product ideas.

Your product prototype is going to

set the stage for everyone involved with your project. After getting a

prototype manufactured, you've got a tangible piece of your idea that you can use to show it off.

So how do you make a product

prototype? Keep reading to find out how to make a product prototype.

How

to Make a Product Prototype

Making a product prototype can be a

simple or complex process, depending on the desired outcome. Typically,

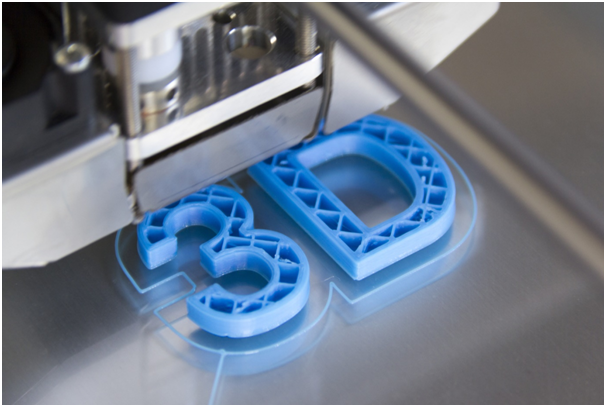

prototypes are made using a variety of methods including 3D printing, CNC

machining, and injection molding.

The most important aspect of making

a prototype is to ensure that the components fit together correctly and that

the overall design is sound.

Creating a prototype is an important

step in the product development process and can make the difference between a

successful product and one that never makes it to market.

You can check out a custom 3D printer to test a prototype and learn more about 3D

printing.

Brainstorm

Your Product Idea

The early stages of product

development are all about generating ideas and fleshing out the concept. This

is typically done through brainstorming sessions, research, and market

analysis.

When you have a product idea, the

first step is to brainstorm what the product would look like, how it would

work, and what it would be made of.

Once you have a clear picture of

your product, you can start to create a prototype.

Find

Materials to Create Your Prototype

To make a prototype, you will need

to find materials that can be used to create a working model of your design.

This may require some trial and

error to find the right materials, but it is important to consider the function

of the prototype and the properties of the materials to ensure that the

prototype will accurately represent the final product.

Assemble

Your Prototype

Once you have the materials, you can

begin to assemble the prototype. This process will vary depending on the

specific design, but it is important to carefully document each step so that

the prototype can be replicated if necessary.

With a completed prototype in hand,

you can then begin to test and iterate on your design to bring your product to

market

Test

Your Prototype

To test your prototype, you'll need

to get feedback from potential users. This can be done through focus groups,

surveys, or interviews. Once you have this feedback, you can make changes to

your prototype.

The main goal of a prototype is

product testing for the feasibility of the design and to verify that the product

functions as intended.

Bring

Your Idea to Life

After reading this article, you

should now have a better understanding of how to make a product prototype.

This is a fundamental step in the

product development process and can save you a lot of time and money in the

long run.

The important thing is to make sure

that your prototype is close to the final product as possible before going into

mass production.

So don't delay. Get started on your

prototype today!

Did you find this article helpful?

Check out the rest of our blogs!